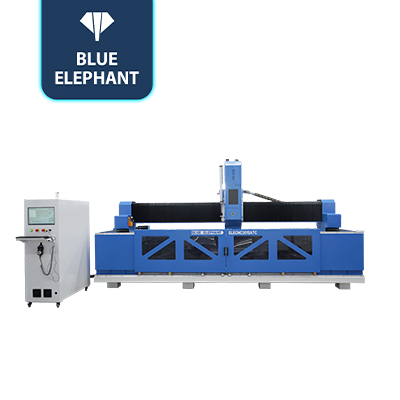

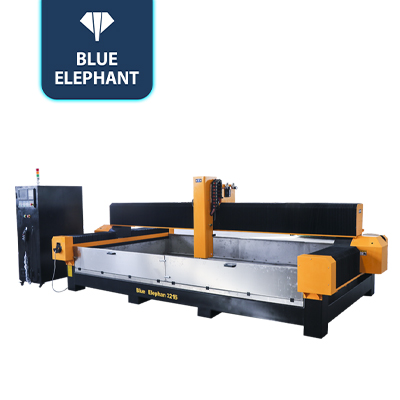

Best Two-process CNC Marble Machining Centeror in Russia, Denmark, Norway

☆This CNC stone processing center is designed with two processes. It has the advantages of low investment cost and high utilization. And it is suitable for various countertop processing.

CNC Machining Center Video

features

- It can help users realize different stone cutting, edging, polishing, and engraving.

- The stone countertop edging and engraving can be switched in one-key operation.

- It can realize fast tool change in 3 seconds, which greatly improves the working efficiency.

Parameters

| Model | ELECNC1530 |

| X,Y axis travel | 1500*3000mm, option: 1300*2500mm; 2100*3000mm; 2100*4000mm, etc |

| Z axis travel | 200mm, option: 300mm, 400mm,etc |

| Spindle type | 5.5kw water cooling spindle*2, |

| Inverter type | 5.5kw inverter |

| Control system | Weihong 95A-3L controller |

| Driving system | 1.5kw servo motor and driver |

| Reducer | Japan Shimpo reducer |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Stone special working table |

| Linear guide | Taiwan linear guide |

| Transmission | X,Y axis: Taiwan Helical Rack and Pinion Z axis: Taiwan TBI high precision ball screw |

| Lubrication system | automatic lubrication system |

| Tool calibration | Autotool sensor calibration |

| Cables | Germany Igus cables with CE, cUL certificate |

| Command Language | G Code & M Code |

| Traveling speed | 60m/min |

| Working speed | 0-30m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working voltage | 220V 1PH/ 3PH 50HZ/ 60HZ 380V 3PH 50HZ/ 60HZ |

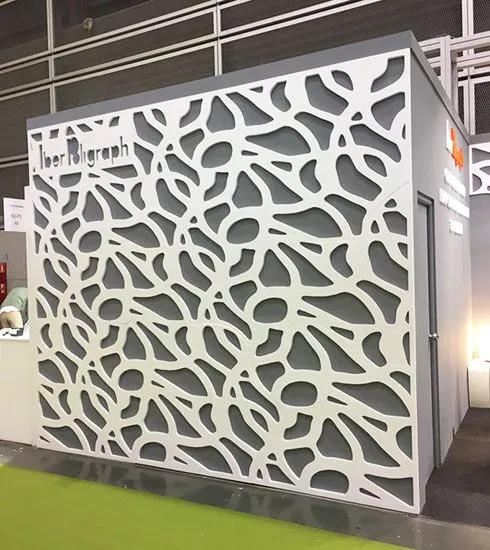

Application

Processing materials:

The quartz countertop processing center is mainly used to process quartz stone, marble, granite, artificial stone slabs, etc.

Applications:

Kitchen cabinet countertops, stone coffee table tops, basin hole cutting, bar counters, bathroom countertops, background wall carvings, etc.

Production Facility

Quality Control & Testing