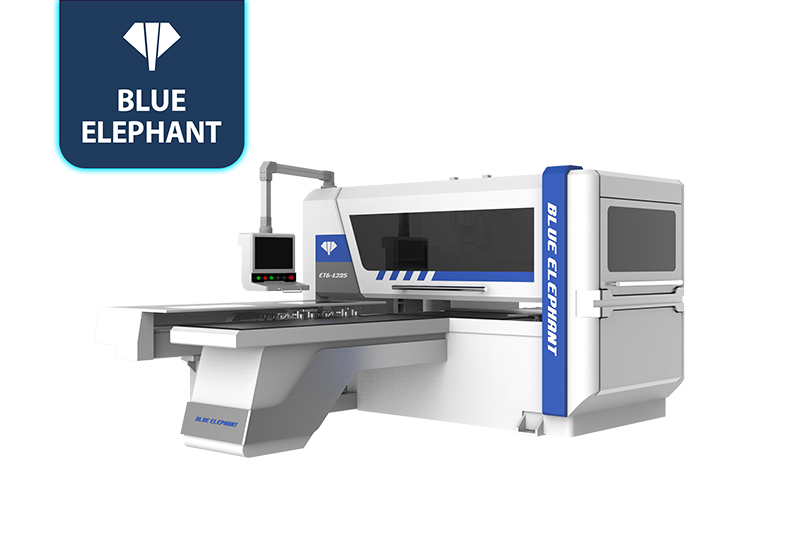

Best Six Sided CNC Drilling Machine for Mass Production of Cabinets

☆This highly automated CNC drilling machine can complete the drilling work on six sides and slotting on two sides of a wooden board at one operation. It can directly connect with a variety of order splitting software and is mainly used for mass production of cabinets, and other panel furniture.

Wood Drilling Machines Video

Features

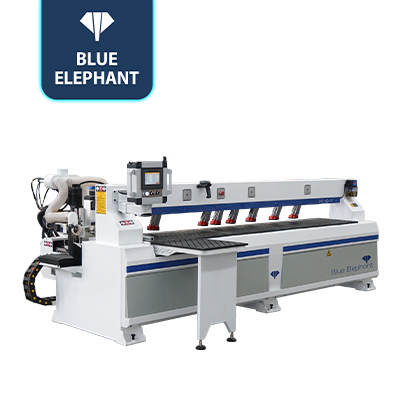

- Using computer operation, the six-sided CNC drill supports CAD drawing and importing files to CAM. Besides, you can also directly import open data formats such as DXF, MPR, xml, etc.

- It is easy to learn and operate this wood drilling machine due to its high-level of automation.

- It can process both small-sized and large-sized panels, and complete drilling and slotting work with high efficiency.

Parameters

| Model | ET6-1325 |

| Working size: | 1300x2500mm |

| Spindle type | 3.5KW Air Cooling Spindle*2 |

| Number of tools | 12 Vertical top drilling+8 horizontal drilling +9 bottom vertical drilling |

| Control system | Blue Elephant Custom System |

| Driver system | Absolute servo motor |

| Transmission | Taiwan helical rack |

| X axis Travel speed | 120m/min |

| Y axis Travel speed | 80m/min |

| Re-positioning accuracy | ±0.03mm |

| Software | Blue Elephant Custom System |

| Working voltage | 220V /380V/ 50-60HZ |

| Machine overall size | 5832*2727*2367mm |

Application

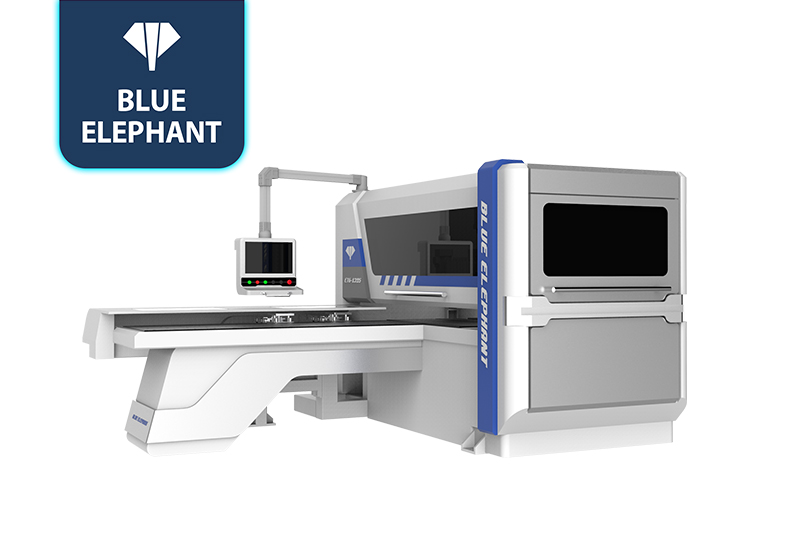

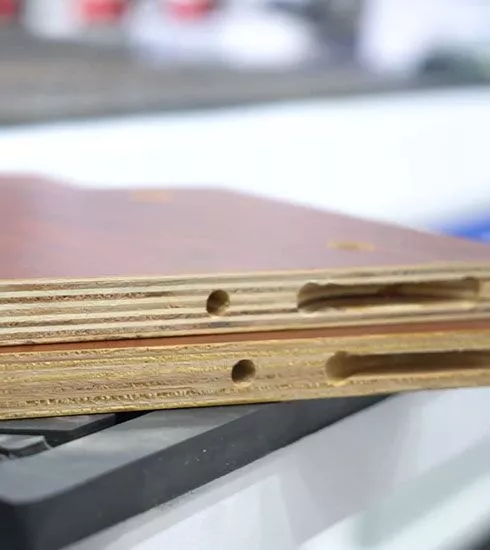

The six-sided CNC drilling machine is an advanced CNC equipment for drilling wooden boards. It is equipped with six-direction drills, which can complete 6-sided drilling at one time without turning the sheet over. The six-sided wood drilling machine are widely used in the production of wooden furniture, such as cabinets, doors, office furniture, etc.

Production Facility

Quality Control & Testing